Ürün Açıklaması:

Alaşımlı Çelik Metal, olağanüstü mekanik özellikleri ve gelişmiş performans karakteristikleri nedeniyle çeşitli endüstriyel uygulamalarda oldukça çok yönlü ve yaygın olarak kullanılan bir malzemedir. Bir alaşımlı çelik türü olarak, bu metal özellikle demirin krom, nikel, molibden ve vanadyum gibi çeşitli alaşım elementleriyle birleştirilmesiyle tasarlanmıştır. Bu elementler, alaşımlı çelik metali zorlu ortamlar ve kritik yapısal bileşenler için ideal bir seçim haline getirerek üstün mukavemet, tokluk ve aşınma ve korozyona karşı direnç kazandırır.

Alaşımlı Çelik Metalin en dikkat çekici özelliklerinden biri, 600 ila 1200 MPa arasında değişen etkileyici çekme dayanımıdır. Bu geniş aralık, uygulamanın özel gereksinimlerine göre uygun sınıf veya bileşimin seçilmesinde esneklik sağlar. Yüksek çekme dayanımı, metalin deforme olmadan veya arızalanmadan önemli gerilmelere ve yüklere dayanabilmesini sağlayarak, otomotiv parçaları, ağır makineler, inşaat ekipmanları ve havacılık bileşenlerinde kullanıma uygun hale getirir. Bu mukavemet özelliği aynı zamanda Alaşımlı Çelik Metalden üretilen parçaların dayanıklılığına ve uzun ömürlülüğüne de katkıda bulunur.

Alaşımlı Çelik Metalin erime noktası, kesin alaşım bileşimine bağlı olarak 1425 ile 1540 °C arasında değişir. Bu nispeten yüksek erime sıcaklığı, metalin yüksek termal koşullar altında yapısal bütünlüğünü korumasını sağlar, bu da özellikle yüksek ısı maruziyeti içeren uygulamalarda önemlidir. Örneğin, Alaşımlı Çelik Metal, mekanik özelliklerini kaybetmeden yoğun ısı döngülerine dayanması gereken aletler, kalıplar ve motor bileşenlerinin üretiminde yaygın olarak kullanılmaktadır. Yüksek erime noktası aynı zamanda metalin performansını daha da artıran çeşitli ısıl işlem süreçlerini de kolaylaştırır.

Isıl işlem, Alaşımlı Çelik Metalin özelliklerini optimize etmede çok önemli bir rol oynar. Bu malzeme için en yaygın olarak kullanılan ısıl işlem yöntemi, su verme ve temperlemedir. Su verme, ısıtılmış metali genellikle su veya yağ içinde hızla soğutmayı içerir ve martensit olarak bilinen sert ve kırılgan bir mikro yapıyı kilitler. Su vermeyi takiben, metal, sertliği korurken kırılganlığı azaltmak için orta bir sıcaklığa yeniden ısıtma ve ardından soğutma işlemi olan temperlemeye tabi tutulur. Su verme ve temperlemenin bu kombinasyonu, Alaşımlı Çelik Metalin tokluğunu, aşınma direncini ve genel mekanik performansını önemli ölçüde iyileştirerek, sertlik ve sünekliğin ince bir dengesini gerektiren uygulamalar için uygun hale getirir.

Alaşımlı Çelik Metalin bir diğer önemli özelliği, uygulanan özel alaşım elementlerine ve yüzey işlemlerine bağlı olarak orta ila yüksek arasında değişen korozyon direncidir. Krom ve nikel gibi elementlerin varlığı, metalin pas ve kimyasal saldırı dahil olmak üzere oksidasyona ve çeşitli korozyon türlerine karşı direncini artırır. Bu, Alaşımlı Çelik Metali, nem, kimyasallar veya aşındırıcı maddelere maruz kalmanın yaygın olduğu ortamlarda tercih edilen bir malzeme haline getirir. Denizcilik, kimyasal işleme ve dış mekan inşaat sektörlerindeki uygulamalar, Alaşımlı Çelik Metalin korozyon direnci özelliklerinden büyük ölçüde faydalanarak uzun ömürlülük ve daha düşük bakım maliyetleri sağlar.

Özetle, Alaşımlı Çelik Metal, yüksek çekme dayanımı, yüksek erime noktası, su verme ve temperlemenin etkili ısıl işlem süreci ve orta ila yüksek korozyon direnci ile karakterize edilen sağlam ve güvenilir bir malzeme olarak öne çıkmaktadır. Bu özellikler toplu olarak, mühendis ve üreticilere mukavemet, dayanıklılık ve zorlu çevresel koşullara karşı direnci dengeleyen bir malzeme sağlayarak, birden fazla sektörde yaygın kullanımına katkıda bulunur. İster yapısal bileşenlerde, makine parçalarında veya aletlerde kullanılsın, Alaşımlı Çelik Metal sürekli olarak üstün performans sunarak, modern mühendislik ve imalatta vazgeçilmez bir malzeme haline gelir.

Teknik Parametreler:

|

Ürün

|

Inconel 600 Alaşımlı Çelik Levha Sacları

|

|

Malzeme Türü

|

Alaşımlı Çelik

|

|

Sınıf

|

Inconel 600, 601, 625, 800, 800HT, 800H, 901, 925, 926, 718

|

|

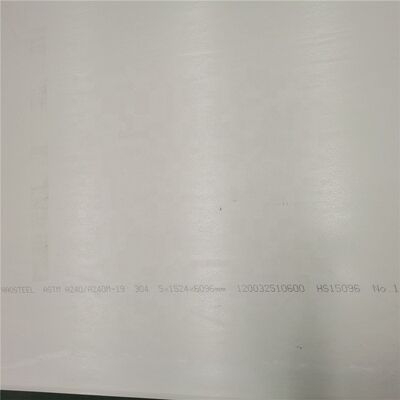

Yüzey

|

Parlak, Siyah

|

|

Kalınlık

|

3 ~ 200 mm

|

|

Çekme Dayanımı

|

600 - 1200 MPa

|

|

Korozyon Direnci

|

Orta İla Yüksek

|

|

Isıl İşlem

|

Su Verme Ve Temperleme

|

|

Kaynatılabilirlik

|

Orta

|

|

Paketler

|

Su Geçirmez Malzeme İle Demetler Halinde

|

Uygulamalar:

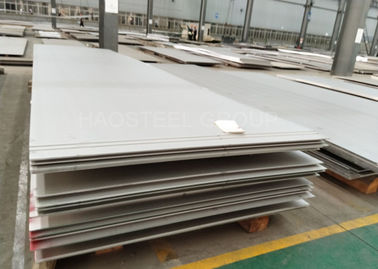

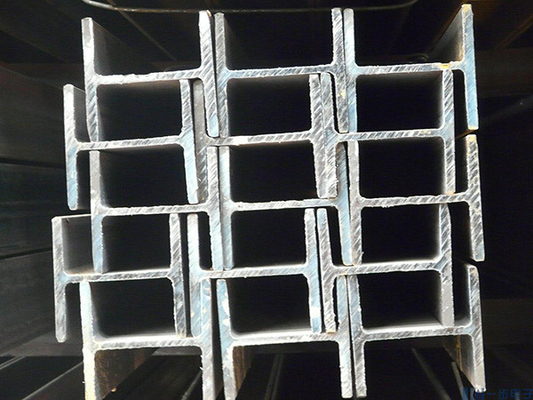

Yüksek kaliteli Alaşımlı Metal Çelikten üretilen Inconel 600 Alaşımlı Çelik Levha Sacları, olağanüstü mukavemetleri ve dayanıklılıklarıyla bilinir. Bu levhalar, mekanik özelliklerini önemli ölçüde artıran su verme ve temperlemeyi içeren hassas bir ısıl işlem sürecinden geçer. 350 ila 1000 MPa arasında değişen bir akma dayanımı ile bu Metal Alaşımlı Çelik, aşırı koşullar altında yüksek performans talep eden uygulamalar için idealdir. Bu levhaların özelleştirilebilmesi gibi boyutlardaki esneklik, çok çeşitli endüstriyel gereksinimlere uyum sağlamalarını sağlar.

Inconel 600 Alaşımlı Çelik Levha Saclarının çok yönlülüğü, onları sayısız uygulama durumu ve senaryosu için uygun hale getirir. Havacılık endüstrisinde, bu alaşımlı çelik levhalar, türbin kanatları, motor parçaları ve yapısal elemanlar gibi yüksek sıcaklıklara ve mekanik gerilmelere dayanması gereken kritik bileşenlerin imalatında kullanılır. Oksidasyona ve korozyona karşı üstün dirençleri, zorlu ortamlara uzun süre maruz kalma sırasında uzun ömürlülük ve güvenilirlik sağlar.

Kimyasal işleme sektöründe, Alaşımlı Metal Çelik levhalar reaktörler, eşanjörler ve boru sistemleri üretimi için gereklidir. Su verme ve temperleme ısıl işlemi, mükemmel tokluk ve termal yorulmaya karşı direnç kazandırarak, bu levhaları agresif kimyasalları ve dalgalanan sıcaklıkları işlemek için mükemmel hale getirir. Özelleştirilebilir boyutlar, mühendislerin levhaları özel ekipman tasarımlarına göre uyarlamalarını sağlayarak verimliliği ve güvenliği artırır.

Enerji endüstrisi de Metal Alaşımlı Çelik levhaların sağlam özelliklerinden yararlanır. Özellikle nükleer ve fosil yakıtlı santrallerde, bileşenlerin yüksek basınçlara ve aşındırıcı ortamlara dayanması gerektiği yerlerde, yaygın olarak kullanılırlar. Inconel 600'ün yüksek akma dayanımı ve üstün mekanik özellikleri, kritik parçaların uzun hizmet süreleri boyunca yapısal bütünlüğünü korumasını sağlar.

Ayrıca, otomotiv ve ağır makine sektörleri, dişliler, miller ve çerçeveler gibi ağır yüklere ve aşınmaya maruz kalan parçaların imalatı için Alaşımlı Metal Çelik levhaları kullanır. Su verme ve temperleme işlemi, sertlik ve tokluk arasında mükemmel bir denge sağlayarak, bu bileşenlerin zorlu çalışma koşullarında güvenilir bir şekilde performans göstermesini sağlar.

Genel olarak, Inconel 600 Alaşımlı Çelik Levha Sacları, özel ısıl işlemden ve özelleştirilebilir boyutlardan kaynaklanan gelişmiş özellikleri nedeniyle çeşitli sektörlerde eşsiz performans sunar. İster havacılık, kimyasal işleme, enerji üretimi veya ağır makineler için olsun, bu Alaşımlı Metal Çelik levhalar, zorlu uygulama durumları ve senaryoları için dayanıklı, yüksek mukavemetli çözümler sunar.

Özelleştirme:

Alaşımlı Çelik Metal ürünümüz, çeşitli imalat süreçleri için uygun hale getiren orta düzeyde kaynak yapılabilirlik sunar. Kalite ve güvenilirliği sağlamak için BV ve SGS sertifikaları dahil olmak üzere sıkı spesifikasyonlara uyarak, özel gereksinimleri karşılamak için özelleştirme hizmetleri sunuyoruz.

Çelik Alaşımlı Metalimizin çekme dayanımı, projeleriniz için mükemmel dayanıklılık ve performans garanti eden 600 ila 1200 MPa arasında değişir. Yüzey kaplamaları hem parlak hem de siyah seçeneklerde mevcuttur ve uygulamanız için en iyi görünümü seçmenize olanak tanır.

Ambalaj için, nakliye ve depolama sırasında ürünü korumak için Metal Alaşımlı Çeliğin su geçirmez malzeme ile güvenli bir şekilde paketlenmesini sağlıyoruz. Endüstriyel ihtiyaçlarınızı karşılayan yüksek kaliteli, özel çözümler sunmak için Alaşımlı Metal Çelik özelleştirme hizmetlerimize güvenin.

Paketleme ve Nakliye:

Alaşımlı Çelik Metal ürünlerimiz, nakliye sırasında maksimum koruma sağlamak için özenle paketlenir. Her bir ürün, nem, korozyon veya darbeden kaynaklanan herhangi bir hasarı önlemek için endüstriyel sınıf malzemeler kullanılarak güvenli bir şekilde sarılır.

Daha sonra ürünler, ek mukavemet ve stabilite sağlamak için boyutuna ve miktarına bağlı olarak sağlam, takviyeli ahşap kasalara veya ağır hizmet tipi çelik kaplara yerleştirilir.

Nakliye için, zamanında ve güvenli teslimatı garanti etmek için güvenilir lojistik sağlayıcılarla ortaklık yapıyoruz. Tüm gönderilere, sorunsuz gümrükleme ve işlemeyi kolaylaştırmak için ürün özellikleri ve taşıma talimatları dahil olmak üzere ayrıntılı belgeler eşlik eder.

Ayrıca, Alaşımlı Çelik Metal ürünlerinizin mükemmel durumda ulaşmasını sağlamak için, özel gereksinimleri karşılamak üzere talep üzerine özelleştirilmiş ambalaj çözümleri sunuyoruz.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!